-

-

WYS140 Hydraulic Gantry Crawler Ship Unloader for Wharf

- Model No.:WYS140

- Max lifting weight :20.6T

- Total weight:140T

- Max. lifting moment:140t.m

- Max. swing torque:5.5 r/min

This heavy-duty wharf ship unloader product is a "heavy, high mobility" energy-saving and environmental friendly bulk cargo handling and grabbing equipment with "dual power" invent

This heavy-duty wharf ship unloader product is a "heavy, high mobility" energy-saving and environmental friendly bulk cargo handling and grabbing equipment with "dual power" invention patent technology of internal combustion engine and 380V electric interchangeable operation, which is imported from Sweden's "modidok" technology in China and manufactured after optimization design and modification on the basis of the structure of a 75 ton mine excavator.

The equipment adopts the original imported Cummins engine, 380V Siemens motor, and two sets of hydraulic power mechanisms driven and controlled by Schneider control system. The machine is designed with a wide body structural beam and a reinforced two-section main boom that can replace positive and negative difference. The maximum lifting weight is 25 tons and the maximum operating radius is 24 meters. Within the operation radius of 5 to 12M, it can be equipped with 5.0m3 clamshell grab or 2.5m3 plum shaped scrap grab.

The electric operation of this equipment is safe and energy-saving, which can save 60% energy consumption compared with internal combustion engine drive; The hydraulic grab of different uses can be quickly replaced, and the multi-purpose function of one machine is realized. The overall features are as follows:

● equipped with "dual power" interworking and interlocking (patented technology) devices for alternating driving operation of internal combustion engine and 380V power;

● Siemens motor is selected for electric operation, and a complete set of electrical components using Schneider control system are equipped with overcurrent, overload, overheating and leakage protection devices;

● equipped with step-down starting device;

● automatic identification of phase sequence to prevent reverse rotation of oil pump;

● power and oil cut-off self-locking and self-stop protective devices of hydraulic system;

● there are multiple compound actions during operation to improve operation efficiency;

● the hydraulic system is equipped with anti tilting torque limit to ensure operation safety;

● the gripper can rotate and change direction 360 degrees automatically;

● when working in the upper control room, there is a dual-purpose air conditioning device;

● it has the lifting function of the cab, and the driver has a good vision during operation, which is safe and efficient;

Progressiveness of the ship unloader electric drive system of the wharf:

● the motor adopts YX3 series new generation high-efficiency and energy-saving motor, with efficiency up to 96%, power factor of 0.9, energy saving and power saving.

● ats48c59q soft starter is used for motor starting control, which greatly simplifies the control circuit. ATS48 series soft start appliances have the functions of limited current, voltage regulation and torque regulation (the actual starting current is less than twice the rated current of the motor, which is quite ideal). The parameters such as starting voltage, current and torque can be set and adjusted according to different motors and loads.

● it has protection functions such as overheating, overload, overcurrent, undervoltage, overvoltage, short circuit, phase loss, phase to phase imbalance, and all protection parameters are adjustable. The built-in display screen can realize real-time self diagnosis and alarm for motor startup operation parameters.

● the engine adopts can bus control and J1939 communication protocol. The control circuit is simple and reliable.

● the programmable monitor integrated with heshman (Weika) monitoring is adopted to realize automatic control of engine throttle. H (heavy load), s (standard) and l (light load) modes can be selected for engine throttle according to different working loads to save energy and fuel. The automatic idling function of the engine is realized with the pressure switch of the hydraulic system to save energy and fuel, and the throttle, maximum and idle throttle of each mode of the engine are adjustable. It can realize the display of engine parameters, hydraulic oil temperature and fuel level, fault self diagnosis and alarm functions, and each alarm point can be adjusted.

● adopt integrated maintenance free aviation technology electric slip ring.

Rear mounted automatic or manual cable reels are available.

Wharf unloading working parameters:

Serial No. | item | unit | parameters | |

1 | Complete weight ( including column and grasping tool) | kg | 100000 | |

2 | Pedrail weight | left pedrail weight | kg | 51000 |

3 | right pedrail weight | kg | 49000 | |

4 | Exterior dimension of the whole machine | total length | mm | 20000 |

5 | total width | mm | 8100 | |

6 | total height (including heighten column 3300) | mm | 10000 | |

7 | Random grasp parameters (Coal grab) | model no . | ZYB6.0L2A(gripper can be selected according to different needs) | |

8 | volume | m3 | 6.0 | |

9 | weight | kg | 4600 | |

10 | opened outer diameter dimension | mm | 4871 | |

11 | closed inner diameter dimension | mm | 4136 | |

12 | gripper opening time | s | 5 | |

13 | gripper closing time | s | 5 | |

15 | power parameter | engine power | kW | 354 |

16 | engine speed | r/min | 1800 | |

19 | motor power | kW | 280 | |

20 | motor speed | r/min | 1490 | |

21 | hydraulic system | Max working pressure of main oil circuit . | MPa | 34 |

22 | Maximum working flow of main oil circuit Control type | L/min | 880 | |

23 | control type | Hydraulic pilot control | ||

24 | Hydraulic oil tank capacity | L | 750 | |

Grab main technical parameter under working .

category | items | unit | parameters | |||

Main operating performance parameters | Theoretical lifting weight at max.radius (including gripper 3600kg) | kg | 6000 | |||

Max. Working radius | mm | 23700 | ||||

Theoretical lifting weight at min. radius (including gripper 3600kg) | kg | 20600 | ||||

Max. Lifting moment | t.m | 140 | ||||

Min. Operating radius | mm | 7000 | ||||

walking speed | Km/h | 3.5 | ||||

max slope | % | 30 | ||||

Ground specific pressure | MPa | 0.078 | ||||

Main action time | Main variable amplitude time | Whole lifting arm |

driving mode | motor | s | ≤12 |

motor | s | ≤11 | ||||

Whole falling arm | motor | s | ≤7 | |||

motor | s | ≤6 | ||||

Max slewing speed | motor | r/min | ≥3.5 | |||

motor | r/min | ≥5.5 | ||||

Deputy variable amplitude time | Whole lifting arm | motor | s | ≤8 | ||

motor | s | ≤7 | ||||

Whole falling arm | motor | s | ≤7 | |||

motor | s | ≤5 | ||||

Gripper action time | open | motor | s | ≤7 | ||

motor | s | ≤6 | ||||

close | motor | s | ≤7 | |||

motor | s | ≤6 | ||||

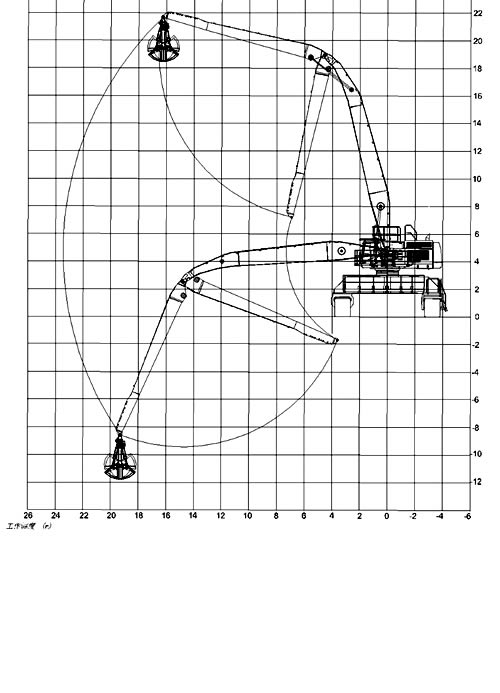

working range